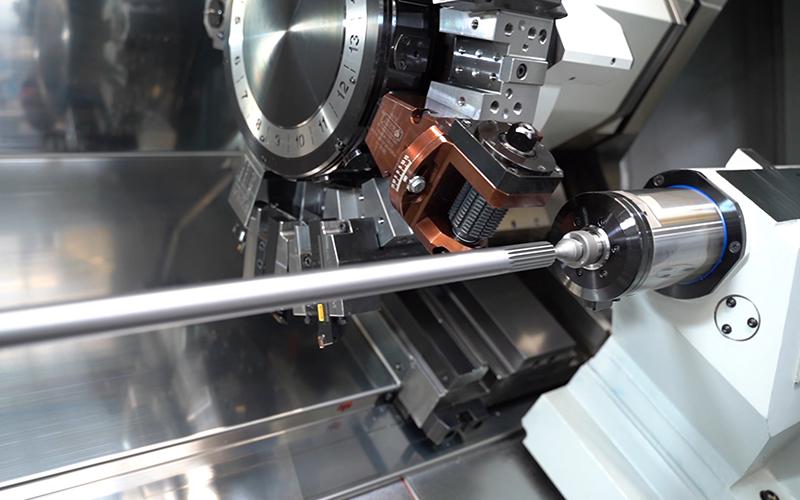

Gear Hobbing On A Lathe . Gear machining on a cnc lathe through hobbing requires a special live toolholder to. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. In principle, turning and hobbing require two different machines. “hobbing” is the metalcutting operation that generates gear teeth using a specialized tool called a hob. The gear blank and hob rotate continuously. The cutter profile on a. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Check out this video to see how you can use an okuma cnc lathe instead of a dedicated hobbing machine to complete gears. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. We present a new application on helical gear.

from www.cmz.com

Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. The cutter profile on a. Check out this video to see how you can use an okuma cnc lathe instead of a dedicated hobbing machine to complete gears. The gear blank and hob rotate continuously. Gear machining on a cnc lathe through hobbing requires a special live toolholder to. “hobbing” is the metalcutting operation that generates gear teeth using a specialized tool called a hob. We present a new application on helical gear. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. In principle, turning and hobbing require two different machines.

Gear Hobbing on a Lathe

Gear Hobbing On A Lathe The cutter profile on a. Gear machining on a cnc lathe through hobbing requires a special live toolholder to. The gear blank and hob rotate continuously. The cutter profile on a. Check out this video to see how you can use an okuma cnc lathe instead of a dedicated hobbing machine to complete gears. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. “hobbing” is the metalcutting operation that generates gear teeth using a specialized tool called a hob. We present a new application on helical gear. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. In principle, turning and hobbing require two different machines.

From koepferamerica.com

CLC Vertical Hobbing Machines Koepfer America Gear Hobbing On A Lathe Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. “hobbing” is the metalcutting operation that generates gear teeth using a specialized tool called a hob. The gear blank and hob rotate continuously. Gear hobbing is a process in which gear is cut by a generating process by. Gear Hobbing On A Lathe.

From www.youtube.com

Gear Hobbing A Spline on a LiveTool Lathe YouTube Gear Hobbing On A Lathe Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. We present a new application on helical gear. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool. Gear Hobbing On A Lathe.

From www.cmz.com

Gear Hobbing on a Lathe Gear Hobbing On A Lathe Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. We present a new application. Gear Hobbing On A Lathe.

From www.machineto.com

Y3180E Gear Hobbing Lathe Machine Gear Hobbing On A Lathe Check out this video to see how you can use an okuma cnc lathe instead of a dedicated hobbing machine to complete gears. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. Gear hobbing is a process in which gear is cut by a generating process by. Gear Hobbing On A Lathe.

From www.pinterest.com

Gear Hobbing Gears, Metal lathe tools, Mechanical design Gear Hobbing On A Lathe “hobbing” is the metalcutting operation that generates gear teeth using a specialized tool called a hob. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. Check out this video to see how you can use an okuma cnc lathe instead of a dedicated hobbing machine to complete. Gear Hobbing On A Lathe.

From www.jskingston.com

Kingston Brand CNC Gear Hobbing Machine YK31125CNC 6 Axis Gear Hobbing On A Lathe Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. The cutter profile on a. “hobbing” is the metalcutting operation that generates gear teeth using a specialized tool called a hob. We present a new application on helical gear. Gear hobbing is a process in which gear is. Gear Hobbing On A Lathe.

From ews-tools.de

EWS gear hobbing Gear Hobbing On A Lathe Gear machining on a cnc lathe through hobbing requires a special live toolholder to. “hobbing” is the metalcutting operation that generates gear teeth using a specialized tool called a hob. In principle, turning and hobbing require two different machines. The cutter profile on a. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob.. Gear Hobbing On A Lathe.

From www.sourceint.com

Gear Hobbing and Shaping For Precision Source International Gear Hobbing On A Lathe Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. Check out this video to see how you can use an okuma cnc lathe instead of a dedicated hobbing machine to complete gears. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or. Gear Hobbing On A Lathe.

From www.exportersindia.com

CNC Gear Hobbing Machine by Microcut Technologies, Cnc Gear Hobbing On A Lathe In principle, turning and hobbing require two different machines. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. The gear blank and hob rotate continuously. Check out this video to see how you can use an okuma cnc lathe instead of a dedicated hobbing machine to complete gears. We present a new application. Gear Hobbing On A Lathe.

From www.youtube.com

Gear Hobbing on Lathe Polygon Turning YouTube Gear Hobbing On A Lathe Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. Check out this video to see how you can use an okuma cnc lathe instead of a dedicated hobbing machine to complete gears. The cutter profile on a. Gear machining on a cnc lathe through hobbing requires a. Gear Hobbing On A Lathe.

From www.pinterest.com

Primitive worm gear hobbing in a lathe YouTube Herramientas caseras Gear Hobbing On A Lathe In principle, turning and hobbing require two different machines. The gear blank and hob rotate continuously. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. The cutter profile on a. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. We. Gear Hobbing On A Lathe.

From www.horizontallathe.com

Gear Hobbing Machine Horizontal Lathe Machine,CNC Lathe Machine Gear Hobbing On A Lathe We present a new application on helical gear. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. Check out this video to see how you can use an okuma cnc lathe instead of a dedicated hobbing machine to complete gears. “hobbing” is the metalcutting operation that generates. Gear Hobbing On A Lathe.

From www.horizontallathe.com

Y30150E Gear Hobbing Machine Gear Hobbing On A Lathe Check out this video to see how you can use an okuma cnc lathe instead of a dedicated hobbing machine to complete gears. Gear machining on a cnc lathe through hobbing requires a special live toolholder to. We present a new application on helical gear. The gear blank and hob rotate continuously. Gear hobbing is a machining process that involves. Gear Hobbing On A Lathe.

From www.horizontallathe.com

Y30150E Gear Hobbing Machine Gear Hobbing On A Lathe The cutter profile on a. Check out this video to see how you can use an okuma cnc lathe instead of a dedicated hobbing machine to complete gears. Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. Gear hobbing is a process in which gear is cut by a generating process by rotating. Gear Hobbing On A Lathe.

From www.cmz.com

Gear Hobbing on a Lathe Gear Hobbing On A Lathe Check out this video to see how you can use an okuma cnc lathe instead of a dedicated hobbing machine to complete gears. We present a new application on helical gear. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. In principle, turning and hobbing require two. Gear Hobbing On A Lathe.

From www.emag.com

Gear Hobbing Machines for Precise Gear Hobbing Gear Hobbing On A Lathe The gear blank and hob rotate continuously. Check out this video to see how you can use an okuma cnc lathe instead of a dedicated hobbing machine to complete gears. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. We present a new application on helical gear.. Gear Hobbing On A Lathe.

From www.yuchun.com.sg

gearhobbingmachine Yu Engineering Pte Ltd Gear Hobbing On A Lathe “hobbing” is the metalcutting operation that generates gear teeth using a specialized tool called a hob. The gear blank and hob rotate continuously. In principle, turning and hobbing require two different machines. Gear machining on a cnc lathe through hobbing requires a special live toolholder to. Gear hobbing is a machining process that involves cutting teeth into a gear blank. Gear Hobbing On A Lathe.

From www.hotonmc.com

China factory low price Universal Gear Hobbing Machine Universal Gear Hobbing On A Lathe Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. Gear hobbing is the process. Gear Hobbing On A Lathe.